Powder Metallurgy Cost Manufacturer – Powder Metallurgy Machinery Equipment – Welfine

Powder Metallurgy Cost Manufacturer – Powder Metallurgy Machinery Equipment – Welfine Detail:

|

Model |

PM bushing |

|

Material |

Fe, Cu, FeCu alloy, stainliee steel, graphite |

|

Style |

Sleeve, Flanged,Spherical,Miniature,Trust Washer, Rod |

|

Size |

1) inner 3-70mm, also can according to your request |

|

Package |

inner packing: plastic bag |

| outer packing: carton, pallet | |

|

Features |

Oil-impregnated; Self-lubricating |

| Wear resistant and long life service | |

| High performance bearing can be in extreme load, low speed reciprocating and oscillating applications | |

| Good thermal conductivity property | |

| Can be used in dirty and corrosive environment | |

| Noise much less than other bearing | |

| Suitable for high static load | |

| Can be applied in widely temperature | |

| Excellent corrosion resistance |

Specification:

Standard tolerance of inside diameter G7

Standard tolerance of outside diameter S7

Recommend shaft tolerance f7/g6

Recommend housing tolerance H7

Powder metallurgy bearing is made of metal powder and other antifriction material powder pressed, sintered, plastic and soaked. It has porous structure. After the infiltration of hot oil, the pores are filled with lubricating oil. In the process of working, the metal and oil are heated and expanded, and the oil is squeezed out of the pores. The friction surface is lubricated. After the bearing is cooled, the oil is sucked back into the pores.

Powder metallurgy bearings can not be lubricated for a long time.

The higher porosity of powder metallurgy bearings, the more oil storage, but the more pores, the lower the strength.

Such bearings are often in the mixed lubrication state, sometimes can form thin film lubrication. They are often used to supplement the difficult and light load and low speed condition of lubricating oil.

According to different working conditions, powder metallurgy bearings with different oil content are selected. When the oil content is large, it can be used under no supplementary lubricating oil and low load. The oil content can be used under heavy load and high speed. The graphite bearing powder metallurgy bearing can improve the safety of the bearing because of the lubricity of graphite itself. Its disadvantage is that the strength is low. Under the condition of no corrosion, it can consider the selection of low price and strength. The iron base powder metallurgy bearing with higher degree is higher, but the corresponding shaft neck hardness should be appropriately improved.

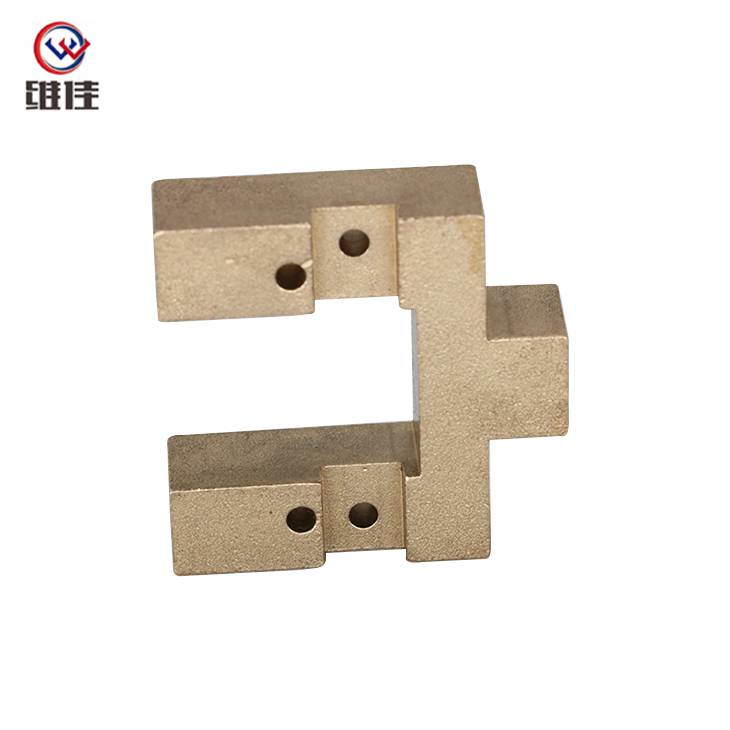

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, trust the first and management the advanced" for Powder Metallurgy Cost Manufacturer – Powder Metallurgy Machinery Equipment – Welfine , The product will supply to all over the world, such as: Panama, Rome, Belize, We are your reliable partner in the international markets of our products. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.